Woco Group

One World

Welcome to Woco Group

We manufacture many components and parts installed in vehicles, such as engines, transmissions, and electronics. Woco plays a decisive role in promoting innovations and technological advances that can reduce emissions.

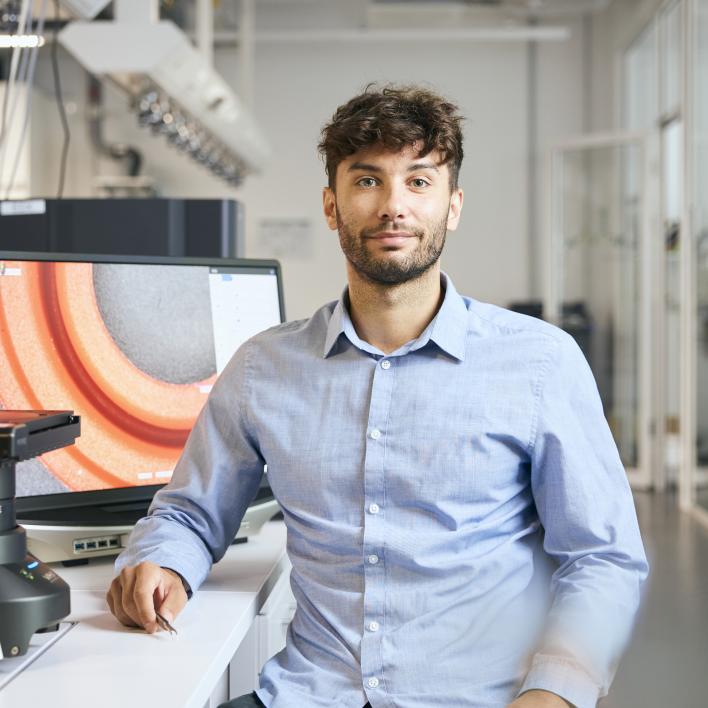

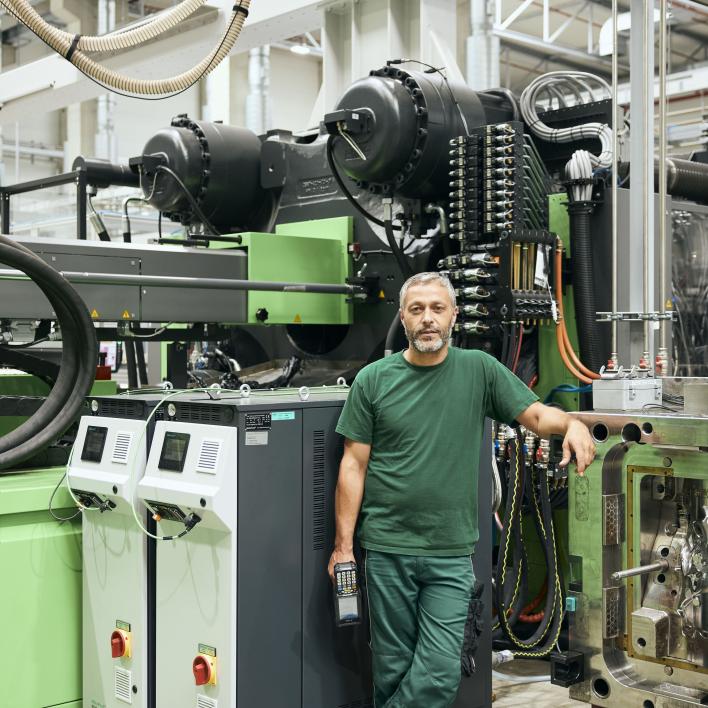

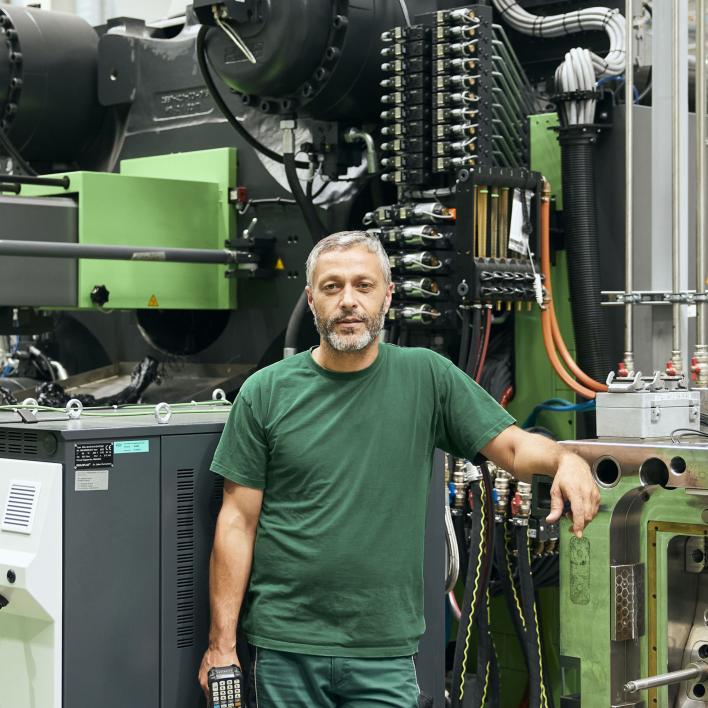

I am Woco

At Woco, passion takes center stage. In our specialist departments, teamwork allows everyone to contribute, expand, and multiply their expertise.

Focus

Woco Group & ESG

Through our business activities, we take responsibility for the environment and people's living conditions.

People at Woco Group

We help the world to turn and are part of the Woco Engineering Competence Center.

Worlds best Thermal Management

If you are looking for range, you will find it in the thermal management solutions from our engineering and development team.

Polymer-based products

Our company is positioned for the future. Our products increase vehicle comfort and stand for a "Green Woco".

Woco is aware of its responsibility towards its customers, employees, and society. We proactively address environmental and social challenges to ensure that our values and principles are upheld. We are committed to science-based sustainability goals and, with our development services, make a positive contribution to the future of the automobile.

We are committed to a future worth living in our shared world.