Our air springs are the perfect base elements for installing machines, vending machines, compressors and ventilators.

Tell our experts about your individual requirements for installing a machine and we will find the ideal air spring solution for you: We can supply you with the four air spring elements SLM, SLM-D, ADS and ALS as well as the high-quality ISR system solution for machine installation. These are air spring elements or diaphragm air spring elements of the highest quality, which are also available with purely electronically controlled level control on request. The ISR system solution combines a computer-controlled machine mounting with a contact-free, electro-pneumatic control system. These quality products guarantee perfect source isolation and receiver isolation. We supply machine feet from professionals for professionals.

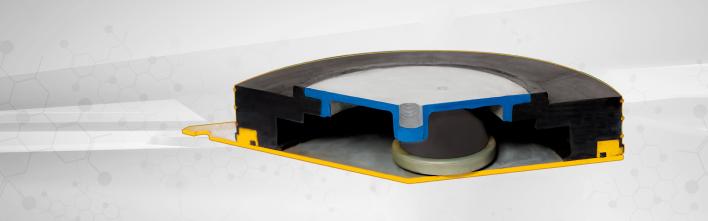

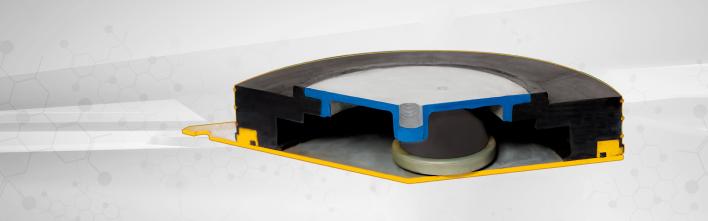

With the ADS Air Spring Element, natural frequencies of between 1.5 and 3 Hz can be achieved for machine bearings.

The highly flexible diaphragm of the ADS air spring element is characterized by its low inherent stiffness. The air volume provided and the highly flexible diaphragm allow natural frequencies between 1.5 and 3 Hz to be achieved.

/media/1125 Download catalog

This Air Suspension Element with purely electronic level control is available in six sizes, each with two different heights.

With six sizes, each available in two different heights, the ALS air suspension element is one of the most versatile diaphragm air suspension elements from our company. The ALS system has a purely electronically controlled level control and, with this load-adaptive control, ensures low-frequency vibration isolation at the highest level.

https://www.wocogroup.com/sites/default/files/2025-08/als_onepager_en.pdfDownload catalog

Our air suspension element without viscose damper

Due to its low natural frequency, the SLM air spring element is very well suited for source and receiver isolation and for solving vibration problems in false ceiling installations.

Our SLM air spring element is characterized by low-frequency source isolation and low-frequency receiver isolation. These air springs are therefore the first choice for measuring machines and measuring table tops in control rooms as well as for mounting fans, air conditioning units, automatic punching presses and nibbling machines. Air is supplied via a standard car tire valve. Wherever vibration problems are particularly extreme, the optionally available, self-controlling level control is used as an alignment element: it is available in mechanical-pneumatic and electro-pneumatic versions.

https://www.wocogroup.com/sites/default/files/2025-08/slm_standard_onepager_en.pdfDownload catalog

Optionally available with automatic level control

The SLM-D air spring element is available in six sizes and corresponds to the SLM series, but with the addition of a viscous damper. The SLM-D air spring element combines the outstanding properties of our SLM air spring in low-frequency source isolation and low-frequency receiver isolation with the effect of an integrated damper unit. This damper unit consists of an elastomer-metal compound with viscose filling. The SLM-D air spring element is mainly used in presses, automatic punching machines, nibbling machines, compressors and packaging systems. If, for example, the vibration problems are particularly extreme in a false ceiling installation, the SLM-D air spring element can be coupled with the optionally available, self-controlling level control. This alignment element is available from us as a mechanical-pneumatic (MPN) or electro-pneumatic (EPN) version.

https://www.wocogroup.com/sites/default/files/2025-08/effbe_slm_08-09.pdfDownload catalog

The Air Spring Control IC System enables PC-controlled machine mounting with a contact-free electro-pneumatic control system.

In our IRC system, we combine the proven elastomer air springs of the ADS system and the SLM series with a new, contact-free electro-pneumatic control system. To achieve this, our engineers have combined the sensor and control valve into a compact assembly and integrated them into the diaphragm air spring. Using a PC and the “Air-Level-Control” software, the parameters of the control unit of the IC system can be viewed, varied within wide limits and permanently stored in the program memory of the control unit. The following parameters in the IC system can be changed: reset accuracy, permissible deflection, reaction time, average level.

/media/1125 Download Katalog

Different versions available with solid granite/aluminum honeycomb core panels and individual vibration dampers

Vibration isolation in perfection: Our Anti Vibration Tables are the ideal solution from our company if your laboratory table needs to remain free from vibrations and mechanical shocks. With table tops made of solid granite or aluminum honeycomb core plate and ideally matched vibration dampers, our laboratory table guarantees the optimum work surface for all applications where testing and measuring equipment must be set up free from unwanted vibrations. Our Anti Vibration Tables are available in various dimensions and with different load-bearing capacities. Our experts will work with you to find the right model, for which different air springs are also available as vibration dampers depending on customer-specific requirements.

/media/1125 Download AVP Katalog

/media/1125 Download AVT Katalog